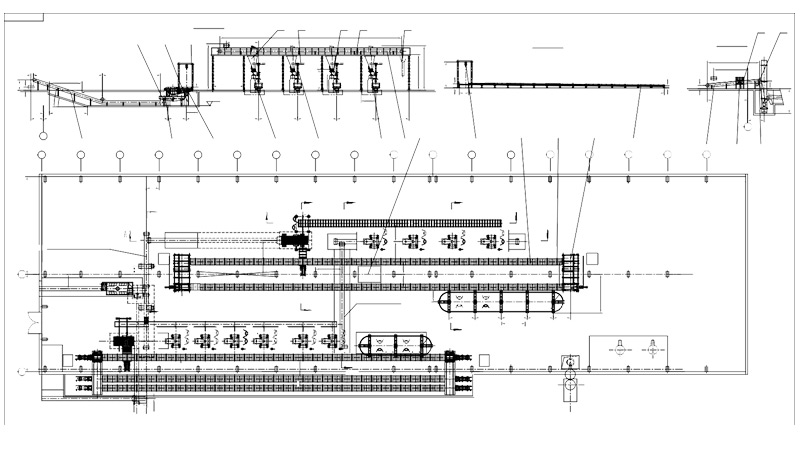

Molding line

1, mechanizationMolding line: is the preferred equipment for batch production casting enterprise ideal.It has less investment, quick effect, reduce the labor intensity, improve the quality of castings, easy to grasp the maintenance, low failure rate, low running cost, etc.

This kind ofMolding lineThe air cushion micro vibration compactionMolding machine(can use more than oneMolding machine) modelling, casting mold conveyer for pouring and cooling.Workers through gas carrying sand and sand mould, under the artificial completed online core, tanks, tanks on the mould in the casting section by pouring ring rail on the complete casting sling bag, after entering the cooling period.After cooling of the mold by pushing box machine into the shakeout machine shakeout.Casting under artificial into sequence, sand box into the box back roller conveyer sent to the modelling of location, old sand into the sand processing system.

2, mechanization: semi-automatic model line can be achieved by means of some auxiliary semi-automatic production.The whole modelling by roller table and turn over the box machine, suitcase, box machine, sand box steering machine, take put weight machine, push the box machine, tong linked box machine, and other auxiliary machinery.This kind of molding line operation more convenient and quick, decorate more specification.

2, mechanization: semi-automatic model line can be achieved by means of some auxiliary semi-automatic production.The whole modelling by roller table and turn over the box machine, suitcase, box machine, sand box steering machine, take put weight machine, push the box machine, tong linked box machine, and other auxiliary machinery.This kind of molding line operation more convenient and quick, decorate more specification.

| Prev:Vertical line | Next:Molding machine |